Orthotics can be useful for pain relief and especially helpful for correct foot positioning after ablation

It has taken us over 4 years to find the custom orthotic that meets our high standard. We have tried so many custom orthotics and we are proud to offer our patients the best in class product.

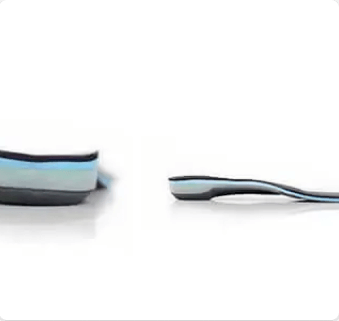

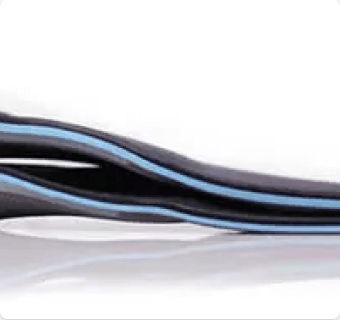

We use a company based on the East Coast to manufacture our custom orthotics. What makes ours so special? Rigidness and Comfort. We have tried so many orthotics. Some are too rigid, some are too bulky, some don’t have the necessary support, some are just made poorly. Our have the perfect combination of structure, rigidity, comfort and very high quality.

Our CNC milled custom orthotics provides the highest quality of tolerances and least amount of human error. From our manufacturer: “There were 3 companies we knew of offering CAD/CAM CNC milling systems, and we made sure to choose the one that offered the highest quality system. This in turn, gives us the flexibility and the adaptability you need to service you to the highest level.”

Our orthotic can be tweaked and adjusted by using a heat gun to give that just perfect fit. In most instances, they come perfect and this is not needed. But just in case, we’ve got you covered.

The Comfort Orthotic allows for maximum range of motion with it’s intrinsic post design, while delivering a deep heel comfort of 14mm. The template is designed to offer maximum surface area and shock absorption and fit inside all various types of sneakers.

Our Support orthotic line is our most functional design. The heel cup is a deep 16-18mm for fuller heel and rearfoot control, and our plastic thickness is calculated by a steeper linear equation, starting from 3mm to our maximum 4.8mm for the most functional yet rigid device you will ever need.

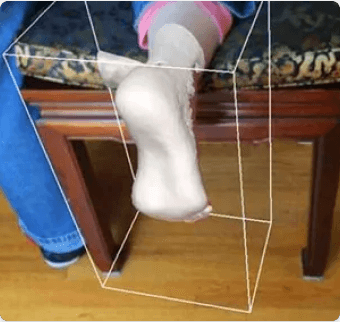

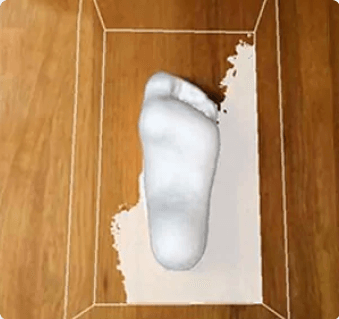

3D scanning technology has made significant advancements in the last 5 years. We use a specially designed 3D Scanner that uses a radical new approach. The scanner creates an imaginary plaster mold of your foot and transmits a file which is fed directly into the CAD/CAM machine to custom fit your orthotic.

The iPad scanner can rotate around the foot during scanning to catch the data around heel and go beyond the plantar surface with laser-precision. This iPad foot scanner not only replaces a traditional foot scanner but also the cast scanner. In fact, it does a better job in scanning than casts, because casts are stationary during the scanning process.

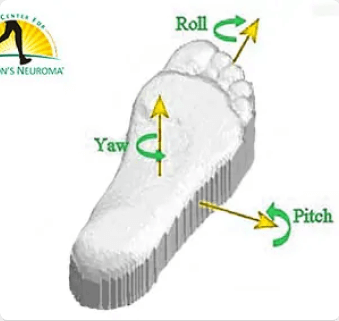

The proprietary takes 3D images of the plantar surface of your foot measuring along the Roll, Yaw, and Pitch axes, along with 3D images of positive and negative plaster-casts and foam-boxes to create imaginary molds of your foot.

The processing/conversion program makes yaw, pitch, and roll adjustments. Other rich processing functions are built into the program which improve the quality of the images. Together, they vastly improve the quality of your custom orthotic.

By providing us with your information you are consenting to the collection and use of your information in accordance with our Terms of Service and Privacy Policy.